Activated Alumina – Applications, Benefits, How It Works And How It Is Used To Dry Natural Gas

Over the years, activated alumina has carved out a place for being the preferred and most efficient desiccant. This post will enunciate the what, how and why of this mentality. Read on to know more.

Activated Alumina, over the years, has become the preferred desiccant for industrial purposes. It is manufactured when aluminium hydroxide is dehydroxylated. Activated alumina desiccant is very efficient when it comes to soaking up moisture as it is a porous substance. On top of this, it is also popular for its impressive surface area and molecular weight. The ratio between these two is so unique that it allows activated alumina to adsorb moisture very efficiently.

The desiccant boasts even-sized pores on its surface – one of the many reasons why the number of activated alumina suppliers in India and in the world, over the years has gone up by many folds.

What is the working principle of activated alumina?

When air or streams of natural gas are passed through activated alumina, the water molecules or the unwanted particles in the air or natural gas stream won’t be able to pass through the tiny molecular pores of activated alumina.

The reason is simple – the diameters of the unwanted molecules are bigger compared to the molecular pores of activated alumina. The result – the air or the natural gas stream that comes out of the other side of the desiccant will be devoid of not only moisture but also other unwanted molecules.

Benefits of activated alumina as a desiccant

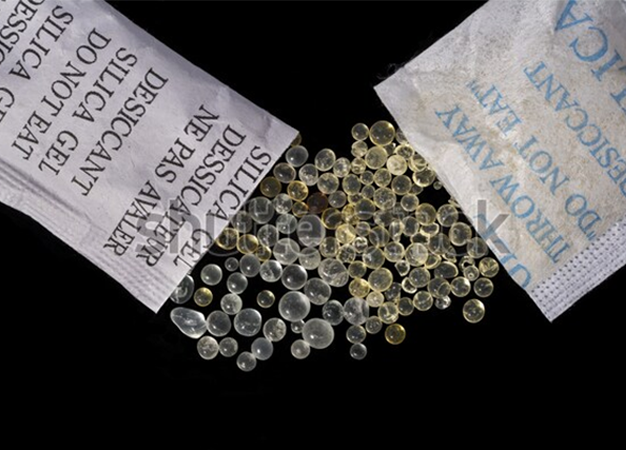

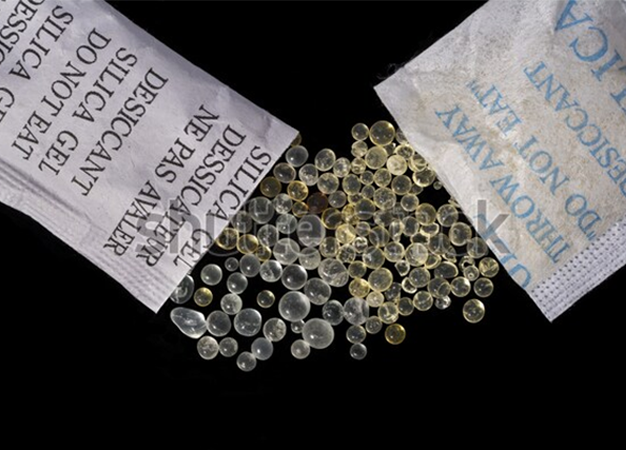

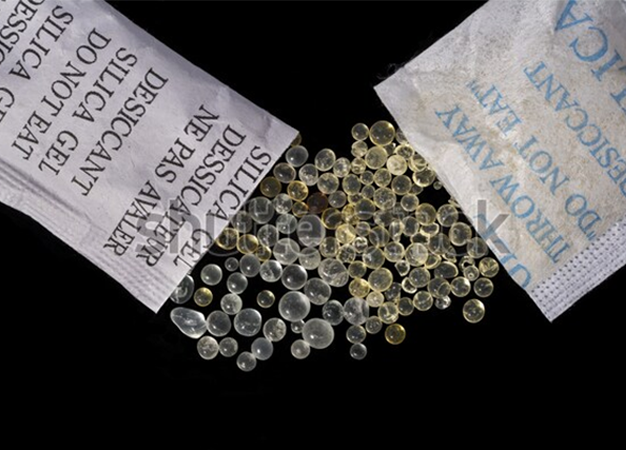

Cleaning and purifying gases or air are possible using a myriad of ways. The most popular among them all is the use of desiccants. Now, when it comes to desiccants, there are plenty of choices available these days for a company. Some of them are molecular sieves and silica gel. These two are superb when it comes to exhibiting adsorption capabilities but activated alumina truly steals the show due to its unique range of benefits in store for the end-user.

These benefits include:

- Activated alumina does not react to most vapours and gases.

- Another factor that makes this the perfect desiccant is its low cost of production (and consumption).

- It is non-toxic in nature and does not disintegrate when it is exposed to water.

- It is known for its ability to resist shocks and abrasions.

- It has the ability to soak up large quantities of water vapour and related unwanted impurities from air and natural gas streams without altering its chemical or physical properties.

- It can be used for extended periods of time since the reactivation cycle for this class of desiccant is nearly unlimited.

Uses of activated alumina

It is mainly used to filter out certain elements from drinking water. The said elements that activated alumina can filter out are:

- Fluoride

- Arsenic and

- Selenium.

It is also used in the assimilation of all the catalysts that are typically present in processes associated with polyethylene production as well as hydrogen peroxide production. It is also used as a means to dry streams of natural gas.

What is natural gas?

Natural gas is a hydrocarbon gaseous mixture that is found in nature. It mainly consists of the following:

- Methane

- Higher alkane types

- Carbon dioxide

- Nitrogen

- Hydrogen sulphide or

- Helium.

Why does it need to be passed through desiccants like activated alumina?

Natural gas also has inert components such as nitrogen and carbon dioxide. These are non-combustible hence they do not come with any heating value for the final product (natural gas), whatsoever.

Furthermore, unprocessed natural gas also has trace impurities such as:

- Hydrogen sulphide

- Water vapour

- Helium

- Oxygen

- Hydrogen and

- Carbon monoxide – all of these do not have any heating value as well for the final product.

On top of this, hydrates such as hydrocarbons and water vapour can form crystalline (ice-like) solids if the temperature drops below 70 degrees Fahrenheit and in turn, may or may not hinder the flow of natural gas through pipelines, over vast distances. This can lead to leaks and even high-risk incidents resulting in explosions and even out-of-control fires!

This is the reason why raw natural gas needs to pass through desiccants like activated alumina in a bid to improve the quality of the end product.

Other uses of activated alumina

Apart from removing impurities from natural gas streams, activated alumina also finds extensive demand in the drying of airstreams in companies that supply compressed air.

It is also used as a desiccant to remove impurities from other gas streams before the same can be packed into cylinders or tankers and then transported to the end-user.

Closing thoughts

In the end, one would not be able to reap all the above-mentioned benefits if they do not procure quality assured activated alumina from licensed chemical manufacturers. To be on the safe side of things, one must conduct a thorough research about the chemical manufacturer they have chosen and ensure that the company has been in the chemical manufacturing business for a while.