All about Various Types of Electrical Connectors!

Electrical sources range in size from small batteries to large power grids. The electrical power connectors allow the transmission of electricity in various forms. Based on the electrical current carried and the application purpose, you must carefully ascertain the type of power connector that may be appropriate for your purpose. To better understand the best-suited connector, it’s helpful to examine how electrical power connectors are classified and the capabilities of each variant.

Generally, electrical connector is classified according to how much voltage they carry. There are three categories of electrical connectors: heavy-duty, medium-duty and, light-duty. Each category name suggests itself, how much voltage each connector can handle.

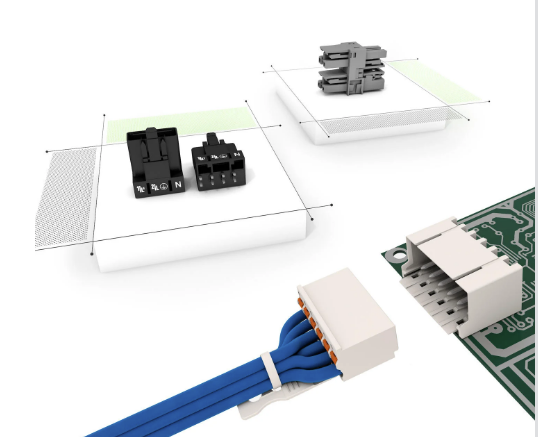

Composition: Most connectors have two main parts- the housing, and terminals for making the connections. The housing is the case used to contain terminals, make connections stable and protect electrical contacts from short-circuiting and causing other environmental hazards. Connector housings are made of moulded plastic and other insulating materials. The other central part of the connectors is terminal. They are pins which provide electrical conduction to make connections secure. They are composed of a metal or other conductive materials, carbon, silicon, etc.

Electrical Power Connector Types

In addition to three general categories of power connectors, numerous different types of power connectors fall under various heads, some include:

AC Power Connectors

This type of power connectors is mainly used to connect equipment to a wall outlet to power the device. Power plugs are for standard-sized devices while industrial AC power plugs are massive electrical wire connectors for heavier industrial application.

DC Connectors

DC connectors are not standardized like DC connectors. A DC plug merely supplies power to smaller electronic devices. Since there are different standards of DC plugs, it’s essential not to use incompatible variants accidentally.

Wire Connectors

The wire connector is used to bring wires together at a common point of connection. Lugs, set screws, crimps, and split-bolt types are examples of this variant.

Blade Connectors

This type of connectors features a one-wire connection. The blade connector is inserted in a blade receptacle, and wire makes contact with receptor’s wire to establish a connection.

Plug and Socket Connectors

Plug and socket connectors consist of male and female sides which fit together snugly. A plug comprises pins and prongs, which securely latches on to corresponding contacts when inserted into a socket.

Insulation-Piercing Connectors

Insulation piercing connectors are useful as they don’t require uncovered wires. A fully covered wire is inserted into the connector, and small device inside opening removes covering as the wire slides into place. The uncovered tip of wire makes contact with a receptor, and power is transmitted.

For some applications, connectors that possess varied features might be preferred. Here are other types of connectors that are available in the market:

Keyed Connectors: Such connectors are designed to connect only when they are in the proper orientation. This prevents accidental damage to pins and prevents users from inserting them in the wrong sockets.

Locked Connectors: A locking mechanism ensures connectors are held in place, preventing breakage of connection when the connector is bumped or jolted.

Hermetically Sealed Connectors: Some applications need an electrical connection to be submerged underwater. Such connectors are built to be fully functional underwater and withstand the pressure of depths.

Water Resistant Connectors: While such connectors can’t withstand being submerged, they protect against water damage from splashes or occasional dampness.

Moisture/Oil Resistant Connectors: Such connectors are designed to protect damage caused by oil or moisture.

EMI or RFI Filtering: The additional features protect connectors from electromagnetic interference (EMI) or radio frequency interference (RFI), impacting circuits carrying power signals.

ESD Shielded Connectors: Electrostatic discharge can damage wiring and components. Such type of connectors provides additional protection.